Structural Characterization & Modeling

Thrust lead: Alberto Cuitiño, Rutgers

# of faculty: 17

Disciplines: Chemistry, Chemical Engineering,

Food Science, Mechanical

Engineering, Pharmacy

THRUST C

Research /

A three-step methodology to analyze the chemical composition and the spatial relationships between API and different excipients.

Raman images from RF1 (left) and from RF2 (right)

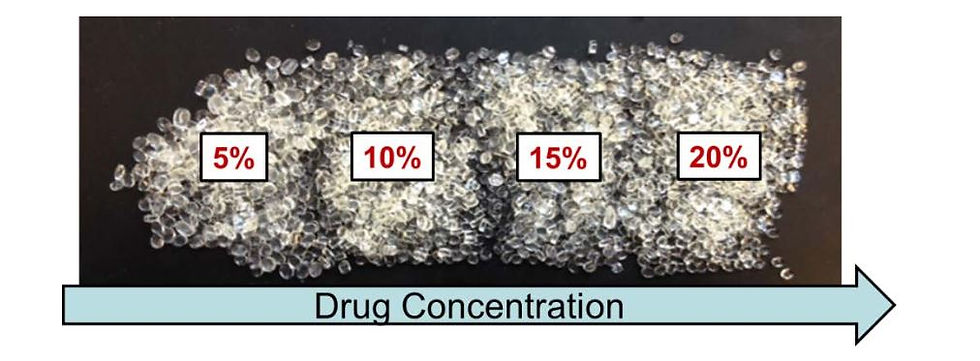

Glassy extrudes of naproxen produced with a Thermo Pharma 11 extruder

A three-step methodology to analyze the chemical composition and the spatial relationships between API and different excipients.

Current Thrust C projects

C1

Synthesis & Characterization of Complex Drug-polymer Polyorganics

C2

Granular Micro-structure Formation & Evolution of Multi-component Powder Systems

C4

Modeling of Granular Structure Evolution in Confined Powder Systems

Summary

Structures are ubiquitous in all materials systems from the subatomic to the macroscopic level. The key question is what feature at a given scale is persistent at the next level of observation. Current research efforts in this area have resulted in a partial understanding for several material systems, leaving a more general answer as a grand and open challenge for the scientific community in the physical and chemical sciences. A derived challenge is to further quantify and model the impact of these persistent structural features in the observed response for enabling a systematic optimization of the structure for desired response. These relevant structural features should then be incorporated in the modeling approach. Within the material science and engineering community, methodologies that incorporate features at a given scale into the observed response at coarser scale are typically denoted as multi-scale methods, where the central issues is how to effectively bridge the length scales.

Projects in this thrust focus on the experimental characterization of the structure and function which will be utilized in conjunction with mechanism-based modeling to reveal the structure-function relationships. This understanding together with simulation tools will be used for the design of delivery systems and the associated manufacturing processes.

Goals

The central objective of this thrust is the development of the scientific understanding and quantification of the role of the structure on the observed function/performance for a particular class of materials: structured organic composites. To establish such a linkage between structure and function, we have identified the following goals:

-

Develop and implement experimental techniques to survey the structural features of the composite systems. All techniques need to provide spatial resolution of the composites to reveal the internal structure. The scale of observation is dependent upon each system ranging from the molecular level to macroscopic level.

-

Develop and implement mechanistic models to predict behavior (function) attendant to the internal structure of the composite system. These models need to account for the critical features of underlying structure, which are necessary to capture the dominant mechanisms associated with a given function.

-

Develop and implement techniques to assess the performance of organic composites systems with emphasis on the capturing the evolution of the structure. In many cases, the measurable quantities represent indirect measures of the sought performance attributes, and thus, their relationships need also to be determined.

-

Design experiments to assess the criticality of the assumed mechanisms as well as to establish measures for the degree of confidence of the developed models using both pre-established and ad-hoc techniques.

Key Accomplishments

Some of the key accomplishments of this thrust are:

-

Assessment of relationship between crystal growth rate, molecular structure and physico-chemical properties, including the determination of relative polymeric impact on growth from super-cooled melts to determine “polymer effectiveness parameter”.

-

Development of new methods for miscibility assessment and phase transitions in supersaturated solutions.

-

Development of novel stabilization strategies of metastable phases for API.

-

Development of multiple powder testing methods (varying consolidation) have been employed to examine flow properties of APIs and excipients, including several novel phase diagrams have been developed (bulk density vs. flow function coefficient; etc.).

-

Development of Complementary NIR and Raman Mapping Characterization of drug particles suspended in polymeric films.

-

Development of characterization techniques for assessing the effect of mechanical energy during processing on evolution of structural disorder and defects on APIs.

-

Development of new computational methodologies based on particle mechanics to predict the macroscopic level properties of compacted granular systems (compactability, compressibility, tabletability) while tracing the evolution of the internal micro-structure including the formation of heterogeneous patterns of densification and residual stresses.

-

Development of suite of techniques for tablet characterization, including LIBS and Chemical Imaging and with X-ray CT, ultrasonic and thermal analysis.

-

Development and evolution of custom dissolution modeling frameworks considering different mechanisms of dissolution/disintegration.

-

Development of simulated in-vivo/ in-vitro bio-accessibility differences in the gastrointestinal tract of APIs with varying particle size distributions using TIM-I®, and development of bio-relevant dissolution methods for assessing buccal drug release from oral films.

Impact

Thrust C has assembled an internationally recognized academic and professional team focused on addressing these interdisciplinary challenges from the molecular to the dosage level scales.

At molecular level, the phase behavior of the drug plays a critical role in the final performance of dosage form. These issues are addressed by the team led by Prof. Lynne Taylor where significant work has been performed regarding the understanding of the crystallization tendency of pure drug compounds upon solidification, and the role of polymers in influencing crystallization behavior of different classes of drugs. This research thus provides a framework to assess potential synthesis of new chemical entities based on their intrinsic crystallization tendency, as well as a framework for the rational selection of polymer.

At the particle level, a team led by Prof. Raj Davé is developing experimental and theoretical methodologies to understand granular system behavior in the complex fluid regime where predicting flow as a function of particle properties, mixture composition and packing conditions has been rather challenging.

In the regime where solids behave as discontinuous solids, a team led by Prof. Cuitiño is developing a new theoretical framework and associated numerical procedures to unveil the heterogeneous distribution of force, density and bonding on highly confined power.

At dosage level, controlling dissolution and bio-availability are important properties in the success of patient therapy. These processes involve factors such as the release of the drug from the drug product/formulation, the rate of dissolution of the drug, and the eventual membrane transport/absorption of the drug. Prof. Germán Drazer leads the team that provides the linkage of dosage’s physical and mechanical properties to in-vitro dissolution. These activities are complementary to the AIR project where non-destructive techniques are the main objective.

In addition, a group led by Prof. Bozena Michniak is advancing the understanding the bio-availability of the drug or API. In particular, the team is studying the effects of simulated physiological environments (such as simulated saliva) on dissolution of oral films and tablet.

A concerted effort to develop characterization methodologies for linking powder, films and tablet properties to structure is a led by Prof. Zafar Iqbal’s team, providing important details about micro-structure and defects (porosity/cracks, molecular-scale disorder) that feed into multi-scale models for predicting the mechanical behavior of granular solids, including the evolution of strength during processing. Molecular dynamic simulations and in-line spectroscopy are also conducted to understand how API crystals are affected in different drug-polymer systems by the molecular binding energy.

Future Plans

The work in the integration thrust will continue towards the development of computational and experimental techniques to bridge material properties and processing conditions to product internal structure. In particular, we will concentrate on processes more prevalent in continuous manufacturing. In particular we are targeting:

-

Control of crystallization by using confinement and heterogeneous nucleation.

-

Assessment of API dry coating on improved content uniformity in the continuous tablet manufacturing line.

-

Development of predictive models for flow-sheet modeling.

-

Use of in-line Raman during film formation.

-

Development of dissolution protocol for oral films in simulated saliva for bio-relevancy.

-

Characterization and modeling of dominant mechanisms of disintegration, swelling, diffusion and erosion.