FACILITES AT PURDUE

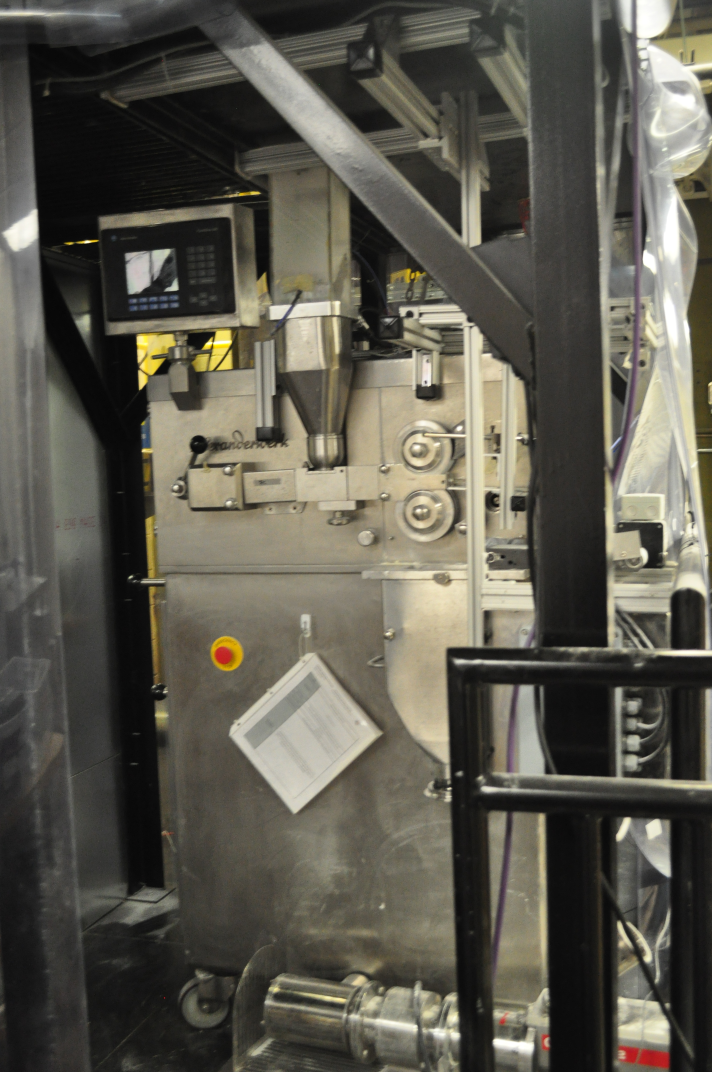

The CSOPS facilities at Purdue University comprises of the new pilot plant, an 1800 sq. ft. of flexible high bay space that is designed to handle particulate material with minimal exposure to operators by virtue of the dust containment system installed. The solid dosage form manufacturing line includes continuous dry and wet granulation equipment, thereby providing additional versatility in processing raw materials that are not amenable to direct compression. The different unit operations are housed in negative-pressure containment modules, which are directly connected to the dust collector to minimize operator exposure. The pilot facility is also equipped with a clean room maintained under negative pressure to be used for powder preparation prior to processing. The integrated manufacturing line are interfaced with different sensors along the production line to provide an eye into the process for enhancement of process understanding. The real-time sensors include instruments for measuring particle size, density, moisture content and blend uniformity.

In addition, Purdue also houses a dedicated Test Bed 3 facility which is a 641 sq. ft. of lab space fully equipped to make drug products by solvent deposition and melt deposition (also called melt extrusion) with real-time monitoring and closed-loop process control.

Additional 2000 sq. ft. of particle characterization laboratory is also available at Purdue that contains a wide selection of instruments for measuring raw material attributes and properties of intermediate and final products.

List of Equipment:

-

Shimadzu MCT-510, Micro-compression tester

-

Bruker MultiMode 8 AFM

-

Retsch PT100 sample divider

-

Humboldt H-3985 sample splitter

-

Gilson SP-1 sample splitter

-

Malvern Mastersizer 2000S particle size analyzer

-

Malvern Morphologi G3-ID

-

Tyler Ro-tap Model E sieve shaker ASTM E-11 sieves

-

Nikon SMZ1500 microscope

-

Nikon Optiphot-2 microscope

-

Innopharmlabs Eyecon in-line/at-line image analysis system

-

Micromeritics AccuPyc II 1340 pycnometer

-

Micromeritics GeoPyc 1360 envelope & T.A.P. density analyzer

-

Agilent Technologies 350 tapped bulk density tester

-

Freeman FT-4 rheometer

-

Schulze RTS-XS ring shear tester

-

PerkinElmer Thermogravimetric Analyzer (TGA)

-

Mettler Toledo HG63 moisture analyzer

-

Binder FED115 drying oven

-

Krüss K100MKII goniometer

-

Photron FASTCAM-X 1024 PCI 100K high-speed video camera

-

NovaStrobe DA115 strobe lamp

-

Carver Press Auto Series 3888

-

Instron ElectroPuls E1000 mechanical testing frame

-

Mechanical Testing Systems (MTS Model C43.504 testing frame

-

Fike explosion suppression system.

-

Negative pressure clean room equipped with HEPA filters

-

Tote blender

-

Chute riffler (powder splitter)

-

Schenck AccuRate AP feeders with Gericke GCM 350 mixer

-

Emerson DeltaV distributed control system

-

10-Station Riva Piccola Rotary Tablet Press

-

Alexanderwerk WP-120V Roller Compactor with Gericke GCM 250 mixer

-

16-Station Natoli Rotary Tablet Press

-

Drucker-Prager Cap powder parameter & powder-surface adhesion instrumented punch-die set

-

UAS 5,000 cfm dust collector

Test Bed 3 equipment:

-

IVEK Digispense 10 temperature-controlled positive displacement pump

-

Newport ESP301 three-axis motion controller for substrate movement

-

Manta G146B machine vision camera for imaging drops

-

Banner D10 high-speed photoelectric sensor for imaging drops

-

Advanced Illumination collimated backlight for imaging drops

-

Omega temperature controllers and heating elements for melt temperature maintenance

-

TETech Peltier devices with TC-48-20 temperature controller for substrate temperature maintenance

-

LabVIEW 2012 with Vision for full-fledged integration and control